Thermal insulation of a building’s exterior envelope is one of the key measures for saving energy and enhancing the comfort of residents and users. Given the increasing importance of environmental issues and climate change, there is a strong emphasis on energy efficiency in new construction. However, it is crucial to recognize that new buildings represent only a small percentage compared to existing ones. Existing buildings are the current consumers of energy and contributors to carbon dioxide emissions. Additionally, the number of existing buildings increases by a few percent each year.

Improving the Thermal Insulation Performance of the Building Envelope

Retrofitting external walls is considered the most effective method for energy efficiency improvement. Enhancing the thermal performance of the building envelope and focusing on execution details using modern and standard materials is one of the best strategies for energy conservation in buildings. When conventional thermal insulation materials and systems are used for insulating buildings, it is essential to consider the details of all external layers of the building. The technical specifications of the materials used in these details are also crucial; factors such as thermal conductivity, density, potential protective coatings for the insulation, and the references used to extract these technical specifications in the plans and documents related to Chapter 19 calculations are among the important considerations.

Conditions for Thermal Insulation Systems According to Chapter 19 of the National Building Regulations

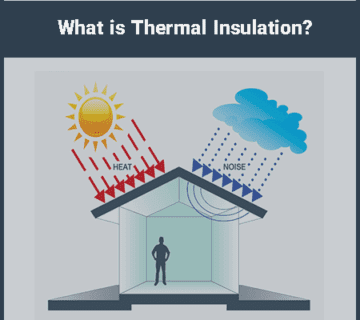

To use thermal insulation to limit the amount of heat transfer in building components, the thermal insulation system must meet the following two conditions:

- The total thermal resistance of the building envelope, including the thermal insulation, must exceed a specified threshold;

- The thermal conductivity coefficient of the insulation used must not exceed a specified threshold.

In some cases, by selecting the appropriate materials for the building envelope, the thermal resistance specified in the regulations can be achieved without the use of additional thermal insulation. According to Chapter 19 of the National Building Regulations, Isolteco 230 plaster, when applied at a thickness of 32 millimeters as per the company’s technical specifications, can be considered as insulation.

Advantages of Thermal Insulation of the Building Envelope with Isolteco

Given the application of Isolteco plaster, studies and comparisons of the thermal resistance of walls or heat transfer coefficients have been conducted in accordance with the thermal insulation requirements for external wall insulation. In this type of insulation, the internal layers of the wall are protected from the effects of weather conditions, but the impact of these factors on the final facade coating and thermal insulation is significantly increased. Additionally, the thermal expansion and contraction, temperature fluctuations, and thermal shocks on the final facade coating must be carefully evaluated. The thermal insulation of the building envelope using Isolteco offers numerous thermal and operational advantages, as detailed below:

- Elimination of the risk of localized thermal bridges

- Protection of the wall against rain penetration

- Protection of the wall against frost and cracking

- Reduction of issues related to condensation, mold growth, and similar problems

- Improvement of the exterior facade performance on weathered external surfaces

- Increased thermal inertia inside the building

- Preservation of interior finishes and aesthetics

- Reduction in management and maintenance costs compared to other insulations

Thermal bridges refer to areas in a building where discontinuities in the thermal insulation of the building envelope occur. In construction details, attention must be paid to these areas, as they lead to a reduction in thermal resistance and an increase in localized heat transfer.

The impact of Isolteco insulation on an energy-efficient building

To achieve the goals of an energy-efficient building, the first step is the effective use of passive strategies such as the building envelope, orientation, building mass ratios, and spatial geometry to reduce energy demand. Modern materials and proper execution in external walls are among the most important strategies in the construction industry. Studies conducted with Isolteco dry and ready-mix mortar, according to the product’s technical specifications as outlined in the catalog, show that it can be used in projects as an enhancer of the thermal performance of the building envelope. Given the ease of application and the range of its use, it can be a highly beneficial recommendation for conventional buildings in the metropolitan area of Tehran, considering the local climate and construction conditions.

Determining Energy Classification and Moving Towards Green Buildings

With the implementation of Article 18 of the Energy Consumption Reform Act, which mandates the determination of energy classification and the shift towards green buildings in Chapter 19, new requirements have been introduced for design and supervision engineers, as well as for clients and builders. The classification of buildings based on one of the three categories, EC, EC+, and EC++, according to the latest chapter, is mandatory. With traditional materials and methods, it is no longer possible to construct buildings that meet these requirements. Therefore, depending on the type of wall materials, the use of Isolteco plaster at the required thickness can achieve compliance.

Additionally, in implementing Regulation 2800 and the facade publication, it is necessary to compare the cost-effectiveness with other insulation methods. It is recommended that the embodied energy, carbon emissions, economic analysis, execution time, and other benefits of this product be categorized in tables. This is crucial for achieving higher energy ratings in buildings and for earning points in the Iranian Green Building Rating System (Sarosabz), as referenced in the design and execution stages.

No comments